Приемная: +7 (374) 222-45-11

Отдел продаж: +7 (917) 371-80-80

ROLLER LIFT WITH CHASSIS COMBINE DRIVE (mechanical drive unit)

Multifunctional logging hoist-station for work in oil and gas wells.

The lift is made in the format of a standard (ISO) 20-foot container, mounted on a MAN, IVECO, MERSEDES, DAF vehicle.

A container platform is installed on the vehicle, with integrated cassettes for downhole equipment, a ladder to the laboratory compartment, hinged boxes for auxiliary tools, containers for transporting radioactive sources.

It is possible to connect connectors for a trailer and install a tow bar.

Additionally, a rear bumper is mounted with a ladder for access to the winch compartment and built-in tool boxes. The hoist can only be operated in conjunction with the chassis.

Winch

The winch consists of a welded frame, a drum, a mechanical transmission, a brake system and a cable laying gauge.

The mechanical drive provides:

- reliability and unpretentiousness work

- lower speed range from 80 m / h

- standard logging methods

- dynamic braking

implemented in two versions:

- mechanical

- pneumatic

The cable-laying machine implements automatic forced laying of the cable on the drum with the possibility of manual adjustment from the operator's control panel.

Quick change of drums is provided.

Winch compartment

The winch compartment accommodates: a winch, cassettes with pneumatic locks for instruments, containers for transporting radioactive sources,

reels for electric cables, floodlights for external lighting, block balance rollers and other auxiliary equipment.

The inside of the compartment is painted with paint resistant to aggressive environments, the floor is covered with anti-slip material and is equipped with a drain pan.

A hatch is built into the roof of the compartment, opening 90 ° to provide visibility, as well as to replace the winch and drum. Technological hatches are provided in the side walls for servicing the winch drive.

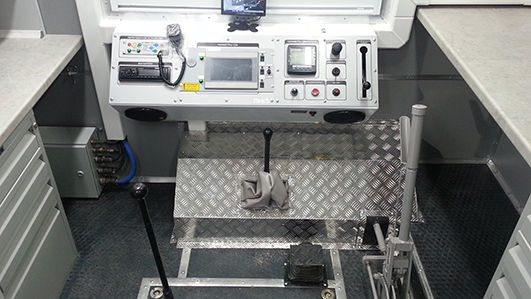

Operator compartment

- dust and moisture resistant

- noise and heat insulated

- equipped with life support systems

(air conditioner, heater, ventilation)

- flexible layout of the internal volume

Control and measurement system

Applicable measuring heads:

- WireHead for lines up to 12 mm in diameter

- any other system agreed with the Customer

Visualization and recording of values:

- by depth, speed and line tension

- differential line tension

- ICE parameters

Automatic modes implemented:

- emergency stop when reaching the limit parameters (tension, differential tension)

- shutdown when reaching the wellhead

- logging of tripping operations (black box)

Installation of blowout equipment control system is possible.

Design features

- diesel generator: up to 12 kW

- additional cassette holders for

downhole equipment

- remote control of engine parameters and location

Specifications

Chassis: KAMAZ, URAL

Cable diameter: 6 to 12 mm

Drum capacity: up to 7000 m

Winch types:

- single drum, single section

- single-drum, two-section

Reducer of the firm KOM

The maximum pulling force on the first two rows of winding is not less than 60 kN

Standard range of line speeds 150 - 8000 m / h

Operating temperature range from -40 ° C to + 40 ° C

Dimensions (with chassis) no more:

- length up to 10,000 mm

- width up to 2500 mm

- height up to 4000 mm

Weight (with chassis): no more than 18 000 kg